New Approaches in Shipping 70mm Prints |

Read more

at in70mm.com The 70mm Newsletter |

| Written by: Ramon Lamarca Marques and Brian Guckian | Date: 10 December 2006 |

|

Cinema managers interested and enthusiastic to run 70mm have communicated to the Workshop that the cost of shipping prints is the biggest barrier to achieving this goal. Therefore, we welcome practical ideas for sharing shipping costs, and / or reducing the weight or size of the overall shipping package, without compromising the ability to protect and handle the prints safely and correctly. |

More

in 70mm reading: 65/70mm Workshop Cinema Lists Internet link: 70mm 5-perf cinemas outside North America 70mm 5-perf cinemas in North America |

Could the existing system be rationalised? |

|

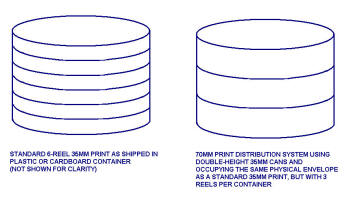

| There is a consensus that the existing shipping format - involving very

heavy reels and transit cases and unchanged since the 1950s - could be

re-visited in today's scenario. Some Projectionists will be familiar with 70mm prints being shipped in 65mm stock cans and wound on cores / bobbins, which is a significantly lighter method.  However these cans are not designed for print distribution, and are

easily dented through continual handling (see photo). This also can prevent

the lids from closing properly, with increasing problems as a result. However these cans are not designed for print distribution, and are

easily dented through continual handling (see photo). This also can prevent

the lids from closing properly, with increasing problems as a result.A better approach could be to use durable plastic 70mm versions of standard 35mm distribution cans. In Europe, most films are wound on cores / bobbins and shipped in these cans, which in turn are usually placed in a plastic or cardboard container. If the can diameter was kept constant, and only the height of the can changed to produce a 70mm version, then 3 no. reels of a 70mm print could be shipped in the same amount of space as a 6-reel 35mm print. If the 70mm print is of 6 reels duration, then the shipping cost of a 70mm print simply becomes approximately double that of a 35mm print. |

|

Fig.

1 Fig.

1Press image to see enlargement A more likely example is that a 70mm print would require up to 9 no. reels, given that such titles tend to be longer, due to their often "epic" nature. Then, the shipping cost becomes multiplied by 3 for 70mm (all Fig 1). Whilst this may still seem high, evidence would suggest that the cost would still be far less than what it presently costs to ship 70mm prints on the heavy shipping reel-plus-transit case method. The lighter core-and-can method is also very attractive from a Health & Safety point of view, and just as significantly, fits a format that shipping depots and couriers are extremely familiar with in Europe (however, we welcome input from other countries where shipping methods are different). A variation on this idea is to use cans and cores, but to ship all the cans in a lightweight Crate on wheels, or in a mobile Cage similar to the type used for supermarket deliveries. This is another shipping format, which, though not used for 35mm prints, is familiar to couriers and freight forwarders. |

|

Important caveats |

|

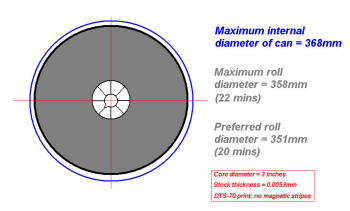

Fig.

2 Fig.

2Press image to see enlargement The diameter of a 35mm film can may impose some reel length restrictions for 70mm, given parameters such as stock thickness, the larger dimensions of the 70mm frame and the presence of magnetic stripes. Another constraint is the need to use at least 3-inch cores to prevent internal strains on the film windings ("core set"). Fig 2 shows how a maximum of 22 mins of 70mm film can be accommodated in a notional 70mm plastic can of internal diameter 368mm / 14.5ins (the same as plastic 35mm cans), wound on a 3-inch core, and assuming a stock thickness of 0.0053 inches. |

|

Sharing Shipping Costs |

|

|

This could have potentially an even greater impact on costs than changing

the shipping method (indeed perhaps both measures could be employed). One

idea is to distribute titles on a constant "tour" format. That is, the print

leaves the holding Archive or Studio Vault and then travels to multiple

venues in an agreed sequence. This could dramatically reduce shipping costs.

However, strict procedures and processes would have to be in place to ensure

print quality is maintained over the duration of the tour. However, perhaps

a Curator, or team of Curators, could be appointed to follow the print and

ensure its safety from venue to venue. Such is the value of such prints that

this approach could be extremely worthwhile, especially if a local Curator

were temporarily appointed in each city the print is shown in. These ideas

of course are all open to discussion. We welcome your comments! |

|

|

|

|

| Go: back

- top - back issues

- news index Updated 21-01-24 |

|