Horizontal VistaVision Projector | Read more at in70mm.com The 70mm Newsletter |

| Written by: By Larry Davee, Century Projector Corporation, 1955 | Date: 24.06.2012 |

Brief | |

|

The full . . . and sometimes amazing story of how the author . . .

and. his organization . . . answered the demand for a horizontal projector

mechanism is described in this interesting article . . . Compressing what is

normally a one or two year project into one month . . . the development of

the equipment for the showing of horizontal VistaVision ... is a wonderful

example of how the industry has geared itself to meet the demands of the new

projection systems . . . In addition to this background information . . .

the reader will find a thorough description of the projector mechanism . . .

with full explanations of how and what each component part has been designed

to accomplish . . . There is a valuable discussion of the problems of heat

and light . . . and how this mechanism combats them . . . There is also

important information about theatre sound . . . and what is accomplished

with the horizontal projector . . . Data on how the mechanism can fit into

new and already existing projection booths is furnished . . . This is a

story worthy of close reader attention. The design of a new projector mechanism normally involves between one and two years of engineering work—and this time they wanted it done in four weeks. They wanted a miracle. And—miraculously—they got it. "They" in the present instance were Paramount's technical chief, Loreon L. Ryder, and his organization. What they wanted in four weeks was an utterly new, unprecedented, horizontal-type projectoi1 for VistaVision. The demand was absurd. But they said the show had to go on. | More in 70mm reading: “In VistaVision, Technicolor and Perspecta sound” 6-7 Juni 2009 Berg der Kinoträume: Paramounts VistaVision VistaVision Review VistaVision Introductions The Technirama Story Internet link: |

Experimental Work | |

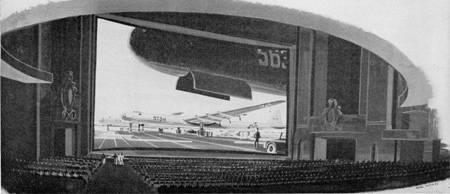

AN ARTIST'S visualization of the screen put into the New York Paramount

designed to present films using horizontal VistaVision positive prints. AN ARTIST'S visualization of the screen put into the New York Paramount

designed to present films using horizontal VistaVision positive prints.Behind this most unreasonable request was some experimental work Ryder and his group had done on the Paramount lot previously. They took an old, abandoned motion picture camera — one built by William Stein back in 1926 and shelved ever since — modernized and altered it, and put it on its side and took pictures with it that way. They had no projector for showing the pictures so they took one of our mechanisms, a Century CC model, and laid it on its side and ran the new picture that way—ran it backwards, in fact. But the quality of that queer showing indicated to Ryder and his fellows that the basic idea was sound and further development worthwhile. Not only were the Paramount people unequipped for proper viewing of their own work but Technicolor, which made the print, had no means of inspecting it after it was made, except by Sending" technicians to the Paramount lot to look at it through Paramount's make-shift set-up. | |

Projected as Photographed | |

|

VistaVision, as every theatreman knows by this time, is made to be projected

in several ways, one of them through a squeeze print in a conventional,

old-style projector. But the greatest value of VistaVision, its real value,

cannot be realized that way. For best results the VV print should be

projected as it was photographed, horizontally. And not through the haywire

device of an ordinary projector placed on its side but through a proper

mechanism made for this type of work. Besides, even if the

projector-on-a-side could give suitable results, which it can't, there

simply is not enough lateral room in most theatres to install mechanisms

with their magazines reaching left and right, instead of up and down.

Moreover, in this case the magazines must be oversize since the film speed

is 180 feet per minutes instead of 90 feet per minute, and 4000-feet

magazines instead of the 2000-feet size are needed for a 20-minute show. Now all this was in 1954 and Paramount had "White Christmas" all beautifully photographed via Stein's once-forgotten 1926 camera, and they wanted to project it for a paying public, on non-existent horizontal projectors, during Christmas week of 1954! We — Century — would kindly produce those projectors, complete and ready for use, in four weeks! How do you produce something that has never existed, solve problems, iron out "bugs" all in four weeks ? The truth is, Century did it, and I'm still gaping, wondering how. We did it, though, and the show went on. We completed six mechanisms. Two went into Radio City Music Hall in New York; two into the Warner Theatre at Beverly Hills, and two to the Paramount lot. | |

Basic Necessities | |

|

You can say that those six mechanisms were crude, and you can say it again.

They did not even have doors—they were open, like European mechanisms. There

was no time to bother with doors. There was no time to bother with anything

except basic necessities. There wasn't even time to draw assembly prints.

Our factory people assembled those six machines without assembly prints —

with nothing to go by but detail prints. Of course, they were our top

mechanics, with plenty of experience with projectors; no one else could

possibly have been assigned to such a zany job. But even so, to assemble

working equipment with no assembly instructions is perhaps one for the

engineering colleges to think about. The four-week wonders thus manufactured turned in outstandingly successful performances in two of the most important theatres in the world. And the two mechanisms that went to the Paramount lot gave Paramount and Technicolor engineers their first chance to see their own work with the picture properly presented, not running backward. | |

Redesign | |

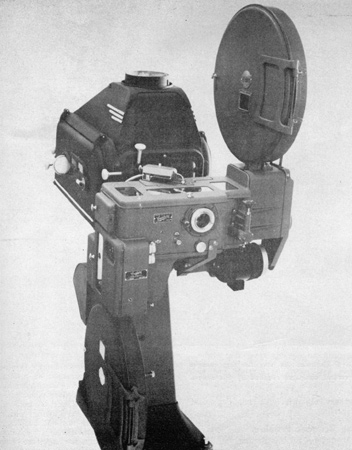

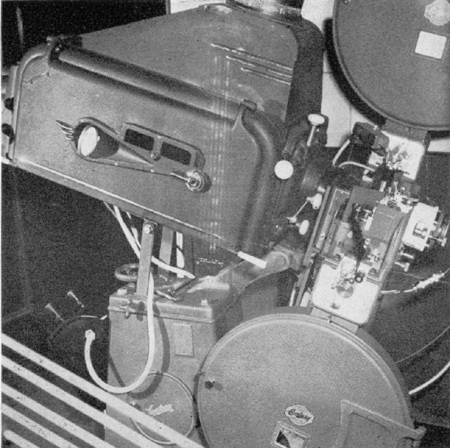

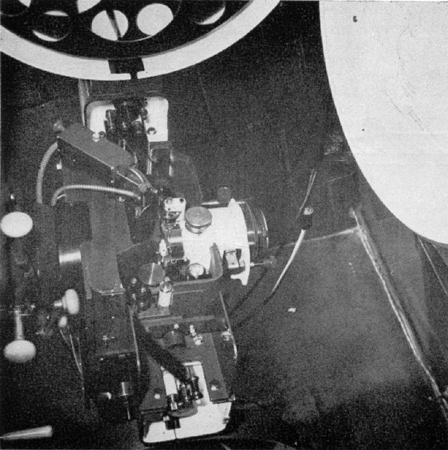

FIG. 1 shows the horizontal projector with the drive motor, the framing

knob, the changeover mechanism above the projector. The projection arc lamp

used is located in the rear of the unit. FIG. 1 shows the horizontal projector with the drive motor, the framing

knob, the changeover mechanism above the projector. The projection arc lamp

used is located in the rear of the unit.Then we redesigned and within the next few months we built and delivered these redesigned Century VistaVision horizontal projectors for many installations. "Strategic Air Command" was shown on the large screen, by horizontal projection, at an Omaha Air Force Base before it opened at the New York Paramount. "We're No Angels," "Seven Little Foys," "To Catch a Thief," and other VV features followed quickly one after another. Paramount and other producers finally got built-to-order cameras and returned the Stein to a well-earned retirement. Short subjects also began to appear in VistaVision and Century's production of the unprecedented horizontal projector mechanisms kept pace with the demand. | |

No "Bugs" Develop | |

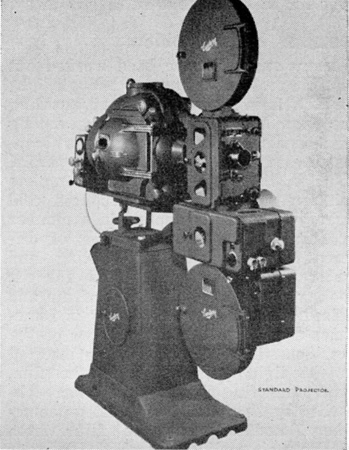

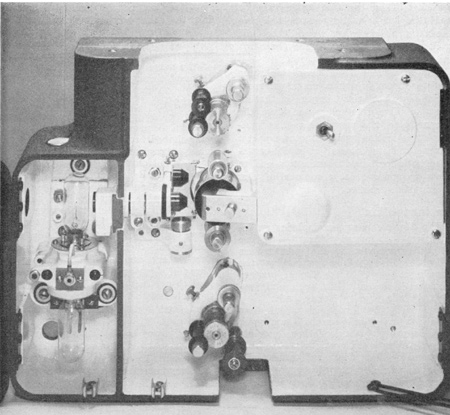

SEEN

here is the standard Century projector. In order to build the

horizontal VistaVision projector a completely new approach was needed. SEEN

here is the standard Century projector. In order to build the

horizontal VistaVision projector a completely new approach was needed.To me, one of the many wonders of the whole incredible business is the fact that these completely new mechanisms, designed in a hurry, built in a flash, have developed no "bugs." This is very nearly unbelievable; all new equipment develops faults that don't show up on the drawing boards or in the testing room, but only in practical use. Almost all new mechanical equipments of any kind — automobiles no less than projector mechanisms — tend to develop unpredicted, unforeseen troubles in each new model, and must be modified after the first models have been sold. Our horizontal projector mechanism is not only new, but original; there has never been anything like it except possibly one of Thomas A. Edison's earlier, abandoned, experiments. It was both designed and produced at unprecedented speed, yet our "bugs" have been almost zero. I can only account for this by the-fact that we have been designing and building projection equipment for so many years, and our people have so much concentrated experience, that they., almost instinctively apprehend and avoid a "bug" as they go along. Standard CC and C models have been giving exhibitors satisfactory and pretty "bug-free" service these many years; but those models were not designed in four weeks, nor assembled without prints, nor installed in commercial use without engineering tests, life tests or any other kind of tests. What Paramount wanted for VistaVision was either a miracle or a near-miracle, and we gave it to them. The advantages of VistaVision in horizontal projection are abundantly visible now on the screens of many theatres. But not all of the advantages are on the surface. The hidden values are perhaps as important as those that are visible. | |

Hidden Values | |

FIG. 2 illustrates the way the film changes course from vertical to

horizontal and back to vertical again, as required by this system. FIG. 2 illustrates the way the film changes course from vertical to

horizontal and back to vertical again, as required by this system.For example, the industry urgently needed larger screens, and VistaVision among other systems, made them possible. But more light is needed for a larger screen. Spread the same light over a larger screen and all you accomplish is to dim the picture. The problem and difficulty of getting more light is fairly well known. More light means more heat. Most of the electricity burned in the projection lamp unfortunately produces heat. Only a comparatively trifling percentage of the energy appears in the visible spectrum, where it is wanted. The rest is concentrated in the infra-red and is definitely not wanted, but must be tolerated. The rest of the problem lies in the fact that the film refuses to tolerate the heat. The film curls up. It loses its smoothness and flexibility and becomes horny—corrugated—buckled—baked out. Such film is spoiled because the pictures on it can't be focussed. If the raised areas are brought to focus by adjusting the projection lens the valleys will be out of focus, and vice versa. And film once buckled can't be restored; it is good for nothing but to be thrown away. | |

Combat Heat Problem | |

|

Many answers have been worked out for this problem of getting enough light

for the larger screen without buckling the film. We at Century were among

the pioneers in this. The answers consisted essentially in cooling. This

partial solution, there will never be a complete solution until somebody

produces cold light, of cooling is applied in a number V>f different ways at

a number of different places. Both air- cooling and water cooling are used;

and for air cooling both steady streams of air and pulsed streams. Water

cooling is sometimes applied to the carbon jaws of the arc. Sometimes a heat

filter is inserted in the light path ahead of the film, protecting the film;

but the heat absorbed by the heat filter must go somewhere, and to keep the

filter from cracking air cooling is applied. Projector film apertures are

Water-cooled. All cooling helps, but VistaVision's horizontal large-frame

projection contributes further help which is not dependent on cooling. | |

Size Reduces Problem | |

|

To understand this further and different help contributed by VistaVision it

is only necessary to remember that all projection lamps act like a burning

glass in that they contain optical elements which focus the light (and

therefore the heat) on the small area of one film frame. But in the case of

VistaVision the burning glass effect is reduced because the VV film frame is

so much larger. The conventional projection frame measures 0.495000 square

inches (0.600 by 0.825) whereas the VV horizontal projection frame is

1.467584 square inches (0.997 by 1.472). Modify these figures very slightly

to make the conventional frame area 0.5 square inches, and that of VV

horizontal projection 1.5 square inches. It will then be seen at a glance

that the VV frame area is essentially three times as large as that of

conventional projection, and therefore will permit use of a screen three

times the previous size before resorting to cooling of any kind. Now, when

cooling is added (and the VV Century-built horizontal projector mechanism is

fully equipped for water-cooling of the aperture) it is evident that doors

have been opened to an enormous advance in screen size. In addition,

Paramount recommends (and we agree) that advantage be taken of the further

benefit inherent in using water-cooled projection lamp jaws also. When a larger screen image is obtained by optical expansion of a film frame that is of conventional size or nearly so, the burning-glass effect continues as in the past to limit the amount of light that can be used to that which the film can endure without buckling. Aperture cooling and lamp jaw cooling still help with any size aperture, but the maximum increase in screen area only becomes possible when the film frame is both artificially cooled and also larger in dimensions. | |

Compact Mechanism | |

|

One of the most important practical facts about the horizontal projection

mechanism is its compactness. This horizontal mechanism occupies no more

space than a conventional vertical projector mechanism. It can be installed

in any theatre regardless of limited front wall space because it takes up no

more room than the equipment that is installed there now. Of almost equal practical importance is the fact that the mechanism can be installed on any standard American projection pedestal. Separate pedestals are available and of course many theatres (especially those with enough front wall space in the projection room) prefer to add a complete VistaVision installation to the equipment they already have, rather than disturb their conventional installation. But other theatres simply take off their existing projectors and soundheads, leaving the lamphouse and pedestal as they were, and put on this VV projection and sound apparatus instead. The choice is a matter of available front wall space first of all, and after that of economics and of program planning. | |

Film Runs Up | |

|

The path followed by the film is exactly the reverse of conventional. Film

does not run down; it runs up. Film speed is twice normal—180 feet per

minute instead of 90. The full new reel is placed in the lower, not the upper, magazine. The film enters the soundhead before, not after, it traverses the projector. The soundhead can be seen at the left of the horizontal mechanism, just above the lower magazine. On emerging from the top of the soundhead the film takes a half-turn and enters the horizontal projector, crossing it from left to right (in this illustration) and passing horizontally before the projection lens. On emerging from the right side of the projector proper the film takes another half turn and runs upward into the upper or take-up magazine. Seen in the illustration (Fig. 1) are the drive motor, the framing knob just above the drive motor, the changeover mechanism above the projector, and the projection lamp at rear. | |

Changes Course | |

|

Also illustrated here (Fig. 2) is the way the film changes course from

vertical to horizontal and back to vertical again. At left the film is seen

coming up from the soundhead and then taking a half-turn course, and running

around what may, perhaps, still be described as the "pull-down" sprocket,

although it pulls up and laterally and we call it the projector feed

sprocket. Just above this sprocket (pictorially above it, that is) the film

proceeds through its "upper loop," then rightward through the gate to the

intermittent sprocket; then through its "lower" loop to what we call the

intermittent loop stablizer

sprocket. Then the film again takes a half-turn into a vertical course and

proceeds upward to what we call the hold back sprocket and the upper

(take-up) magazine. The film compartment, as this same picture shows, provides abundant room for the projectionist's fingers in threading the film into place, making the proper loops and completing all adjustments; it is amply illuminated by two lamps, and its interior is white-enamelled both for added illumination and to show up, and encourage removal of, dirt or emulsion crumbs. | |

An Innovation | |

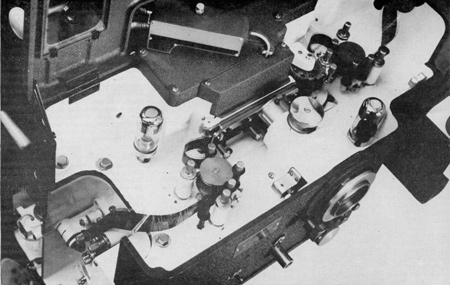

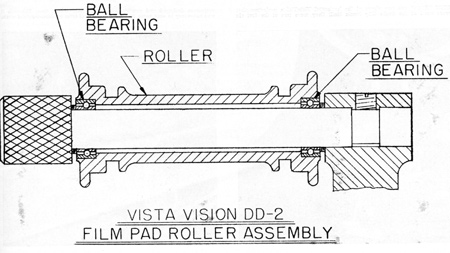

FIG. 3 demonstrates how ball bearings were used in the pad rollers. This

represented the first time that ball bearings were Bo employed. FIG. 3 demonstrates how ball bearings were used in the pad rollers. This

represented the first time that ball bearings were Bo employed.The film compartment includes an innovation — an industry "first" — the use of ball bearings in the pad rollers (Fig. 3). These rollers rest against the sprockets; they hold the film in engagement with the sprocket teeth and prevent it slipping off the teeth; they rotate with the film motion, but they have never before been ball-bearinged. Here is precisely one of those possible "bugs" I mentioned previously—the kind of trouble that does not necessarily show up at all in manufacturers' tests. Film formerly ran at 90 feet per minute. In VV horizontal projection it runs at 180 feet per minute. Would the pad rollers give trouble at the increased speed? There was no way to find out short of prolonged testing because they might not give trouble at first-, when new and round, but only afterward when they had become somewhat worn through extended use. But we have been making projectors for a long time and our people sensed that possibly here was a place where trouble could show up—later on, not immediately—and we felt that the relatively trivial cost of putting in ball bearings was an abundantly justifiable insurance. So we put in ball bearings. It is a step representative of the same general principles we have followed throughout. | |

Power | |

|

Power is applied to the mechanism through Gilmer belts. These belts have

gear-shaped corrugations along their inner edges, and they run on geared

pulleys, not on ordinary ones. They cannot slip at all as ordinary belts do,

and for that reason are called Gilmer timing v belts. They do, however, have

some of the flexibility of belts, which drive shafts and chains do not have;

they tend to damp out and not to transmit vibration, because of their

flexibility; they are long-lasting and decidedly economical. Three of them

are used in the horizontal projector. One transmits power from the drive

motor to the projector mechanism, and by its resilience practically

eliminates motor vibration. A second carries power to the hold back sprocket

above mentioned, and a third drives the upper or take-up magazine. Power transmission within the mechanism and the soundhead follows the simple single-shaft system that has proved so successful through the years in conventional Century projectors. There is one straight power shaft, belt-driven, which drives the sprockets, the intermittent movement, the shutters, the governor and the soundhead. There are two shutters, which lie between the film and the lamphouse, and by their location contribute still further to the amount of light that can be used without damage to the film, since during those intervals (48 in each second) when the screen is momentarily dark, the film is dark too and unnecessary heat does not accumulate at the aperture. | |

High Sound Quality | |

FIG. 4 illustrates the reproducer used in the horizontal projector. Film

runs up through the soundhead and not in normal downward direction. FIG. 4 illustrates the reproducer used in the horizontal projector. Film

runs up through the soundhead and not in normal downward direction.The sound that accompanies Vista-Vision is, as most showmen know by now, not only simplified but highly improved. Because of its simplicity it combines extremely high sound quality with low cost; and like the picture, the sound is available in several price ranges. As the best picture, in our opinion, is the horizontally projected VistaVision, the best accompanying sound is the three-dimensional (not stereo) Perspecta Sound; and our sound-head is fully designed to get the very finest out of the film that the studio put into it. | |

Flutter Suppressor | |

A

view of the horizontal VistaVision projectors that were used at the Radio

City Music Hall. They were two of the first six projectors designed and

constructed in only four weeks time. Although it was necessary to omit some

of the refinements of later models, they did work. A

view of the horizontal VistaVision projectors that were used at the Radio

City Music Hall. They were two of the first six projectors designed and

constructed in only four weeks time. Although it was necessary to omit some

of the refinements of later models, they did work.As in the case of the projector, so with the soundhead, we had problems to solve in a rush, but we did solve them. They centered essentially on our flutter suppressor, which has always been better than good—0.08 per cent flutter content where the Academy standard flutter minimum allows practically twice that; 0.15 per cent flutter content. Now, however, we faced the problem of making our flutter suppressor perform equally well not only at twice the former film speed but also against gravity where in the past applications it worked with gravity. The whole suppressor mechanism had to be recalculated, to the same formula as in the past, but to new conditions. And the new parts had to be built, and assembled without assembly drawings and put into commercial use without engineering tests. After the equipment had been put into theatres and was working for paying spectators, we made flutter tests in the theatre, and established beyond doubt that our new flutter performance is as good as in the past—0.08 per cent flutter content, just as in our model CC. | |

Doubles Speed | |

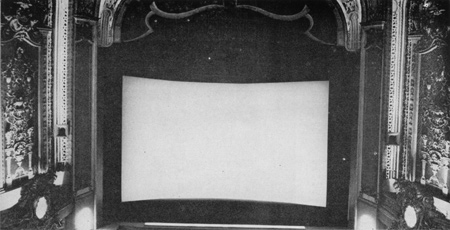

THE HUGE screen at the New York Paramount is seen. This theatre was among

the very first in the country to equip itself especially for the showing of

horizontal VistaVision. The special projectors helped to paint the screen

with an image that was clear, no distortion, and excellent depth of focus. THE HUGE screen at the New York Paramount is seen. This theatre was among

the very first in the country to equip itself especially for the showing of

horizontal VistaVision. The special projectors helped to paint the screen

with an image that was clear, no distortion, and excellent depth of focus.The superiority of Perspecta Sound, however, derives essentially from the fact that the film runs at double the former speed. Flip any phonograph record to make it run faster momentarily and you will hear the pitch of the sound jump a bit. The striations are passing under the needle faster; the needle is vibrating a little faster, and the pitch of the sound goes up proportionately. The frequency content of any phonograph recordings could be increased by making' them and playing them at greater speed; and as you know the phonograph speed for many years was 78 rpm. With more modern record materials it became possible to get the striations smaller, crowd more of them into a given space; so it was no longer necessary to run the record as fast as before and record speeds came down to 45 and 33 rpm. But in photographic soundtracks it has never been found practical either to reduce the striation size or to narrow down the light beam (which may be compared to the needle point in phonographic sound). It has never been found possible to reproduce more than about 9,000 cycles of sound, if that, with reasonably full volume under the old conditions. And as hi-fi record players, frequency modulation radio broadcasting, and other improved sound reproducers came into common use, the theatre, which at one time offered the best sound available, fell back by comparison, and at its best did no better than the customers could get from a hi-fi platter spinner at home. Just as the screen had to be enlarged and brightened to compete with the television picture in the living room, so also sound needed to be improved to help it compete with the hi-fi record player and the fm radio. | |

Sound Frequency Reproduction Increased | |

Another

view of the horizontal VistaVision projectors that were used at the Radio

City Music Hall. They were two of the first six projectors designed and

constructed in only four weeks time. Although it was necessary to omit some

of the refinements of later models, they did work. Another

view of the horizontal VistaVision projectors that were used at the Radio

City Music Hall. They were two of the first six projectors designed and

constructed in only four weeks time. Although it was necessary to omit some

of the refinements of later models, they did work.The VistaVision-PerspectaSound film that runs at double speed has the effect of doubling the upper limit of sound frequency reproduction. An upper limit of 16,000 cycles is the maximum necessary; few ears can go higher than that and most ears cannot reach it; 8,000-cycle reproduction from conventional film is increased to 16,000 cycles with VistaVision film, and that problem is solved—at least, as far as concerns the soundhead. What the amplifiers and speakers do with this improved sound after it has been delivered to them is another story. Our VistaVision-PerspectaSound reproducer head is pictured here (Fig. 4). Only the upper exciter lamp works since the lower one is a pre-focussed spare. The lens tube is seen aligned with the upper lamp filament, and the sound drum, which holds film flutter down to half as much as even the Academy permits, is aligned just right of the lens tube. Film runs through this soundhead in an upward direction as already explained, not downward. The pre-focussed spare exciter lamp serves the cause of economy as much as anything else; modern exciter lamps do not burn out very often, but they do of course burn out. Any projectionist who is doubtful of the condition of his lamp will be inclined to replace it, not taking chances with his show for the sake of a lamp bulb; but if he has a pre-focussed bulb in the soundhead, available at the flick of his wrist, he will be less inclined to discard lamps that probably have a good bit of life still left. The soundhead film compartment, like that of the projector mechanism, is amply and abundantly large enough for careful and accurate threading of film, and white enamelled for visibility and cleanliness. VistaVision and PerspectaSound are, of course, furnished by the producers to the choice of the exhibitor. They can be obtained in conventional prints, with conventional frame dimensions, run in conventional projectors and reproduced through conventional sound equipment— nothing need be changed. But the show will not be particularly improved. The picture can also be projected through expander lenses, but, although the image will be larger, its full benefits still will not be realized. | |

Some Advantages | |

|

When played through a horizontal projector the VistaVision image can be made

very large without adding distortion; it can be brilliantly illuminated

because of the triple area of its frames which accommodates more light and

heat without damage to film; and picture grain is greatly reduced because

there is less magnification both in the photography and in the projection,

owing again to the larger frame size. Similarly the sound, reproduced through a conventional soundhead, can be played in the conventional way. Reproduced through the Century Vista-Vision soundhead it can still be played through conventional equipment in the conventional way, but the upper frequency of reproduction will be 16,000 instead of 8,000, provided the amplifiers and speakers can handle 16,000. However, the sound will not only go up to 16,000 cycles in pitch, it will also become three dimensional (not stereoscopic) if the necessary three channels and a control panel are provided. An inaudible control frequency is recorded in the track; it acts on the control panel (if installed) and automatically adjusts the volume from the three sets of speakers from moment to moment. Thus the sound (albeit the same sound, not three different sounds) appears to originate in different locations, according to the action on the screen. And the result, new sound and new picture, is a completely new show, beyond all comparison superior in attraction to the old-fashioned movie. I am proud, that my company had so large a part in bringing this new entertainment into existence; a new pattern of entertainment so wonderful that not only is Paramount using it, but Warners and MGM are reported to be adopting it too. It's a big thing to have had a big share in. But what I am proudest of of all is that we did it — mirabile dictu we did it — in four weeks! | |

| Go: back - top - back issues - news index Updated 21-01-24 |