|

“Almost like a real web

site”

|

IN7OMM.COM

• Search |

Contact

• News |

e-News |

• Rumour Mill |

Stories

• Foreign Language

• in70mm.com auf Deutsch

WHAT'S ON IN 7OMM?

7OMM FESTIVAL

• Todd-AO Festival

• KRRR! 7OMM Seminar

• GIFF 70, Gentofte

• Oslo 7OMM Festival

• Widescreen Weekend

TODD-AO

• Premiere |

Films

• People |

Equipment

• Library |

Cinemas

• Todd-AO Projector

• Distortion Correcting

PANAVISION

• Ultra Panavision

70

• Super Panavision

70

|

|

|

VISION, SCOPE & RAMA

1926

Natural Vision

1929 Grandeur

1930 Magnifilm

1930 Realife

1930 Vitascope

1952 Cinerama

1953

CinemaScope

1955 Todd-AO

1955 Circle Vision

360

1956

CinemaScope 55

1957 Ultra

Panavision 70

1958 Cinemiracle

1958 Kinopanorama

1959 Super

Panavision 70

1959 Super Technirama 70

1960 Smell-O-Vision

1961 Sovscope

70

1962

Cinerama 360

1962 MCS-70

1963 70mm Blow Up

1963 Circarama

1963 Circlorama

1966 Dimension 150

1966

Stereo-70

1967 DEFA 70

1967 Pik-A-Movie

1970 IMAX / Omnimax

1974 Cinema

180

1974 SENSURROUND

1976 Dolby Stereo

1984 Showscan

1984 Swissorama

1986 iWERKS

1989 ARRI 765

1990 CDS

1994 DTS / Datasat

2001

Super Dimension 70

2018 Magellan 65

•

Various Large format

| 70mm to 3-strip |

3-strip to 70mm |

Specialty Large Format |

Special Effects in 65mm |

ARC-120 |

Super Dimension 70

| Early Large Format

• 7OMM Premiere in

Chronological Order

7OMM FILM & CINEMA

• Australia |

Brazil

• Canada |

Denmark

• England |

France

• Germany |

Iran

• Mexico |

Norway

• Sweden |

Turkey

• USA

LIBRARY

• 7OMM Projectors

• People |

Eulogy

• 65mm/70mm Workshop

• The 7OMM Newsletter

• Back issue |

PDF

• Academy of the WSW

7OMM NEWS

• 2026 | 2025 | 2024

• 2023 |

2022 |

2021

• 2020 |

2019 |

2018

• 2017 |

2016 |

2015

• 2014 |

2013 |

2012

• 2011 |

2010 | 2009

• 2008 | 2007 |

2006

• 2005 | 2004 |

2003

• 2002 |

2001 |

2000

• 1999 |

1998 |

1997

• 1996 |

1995 |

1994

|

|

in70mm.com Mission:

• To record the history of the large format movies and the 70mm cinemas

as remembered by the people who worked with the films. Both during

making and during running the films in projection rooms and as the

audience, looking at the curved screen.

•

in70mm.com, a unique internet based magazine, with articles about 70mm

cinemas, 70mm people, 70mm films, 70mm sound, 70mm film credits, 70mm

history and 70mm technology. Readers and fans of 70mm are always welcome

to contribute.

•

Disclaimer |

Updates

• Support us

• Testimonials

• Table of Content

|

| |

| |

Extracts and longer

parts of in70mm.com may be reprinted with the written permission from

the editor.

Copyright © 1800 - 2070. All rights reserved.

Visit biografmuseet.dk about Danish cinemas

|

| |

Todd-AO

Description

of Todd-AO

Mark III Printer Principle

|

This article first appeared in

..in 70mm

The 70mm Newsletter |

|

Written by:

Dr. W. P. Siegmund,

American

Optical Company,

USA.

Reprinted

from American Optical Research Center files

dated July 31, 1957.

|

Issue 53 - June 1998 |

|

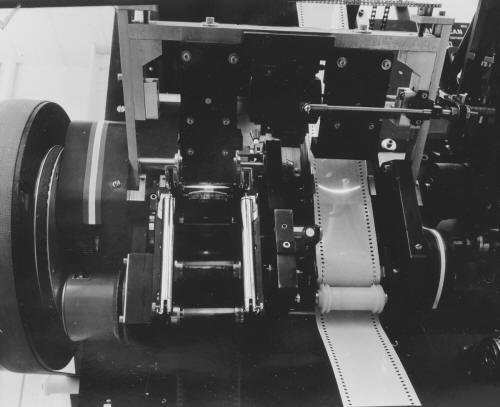

Side view

of the Mark III printer showing the supply reels at the top and the take-up reels at

the bottom. The closed reels are for the raw stock and the open reels are

for the negative. The circular pulley in the center is the heavy flywheel on

the printing drive to insure smooth motion. Side view

of the Mark III printer showing the supply reels at the top and the take-up reels at

the bottom. The closed reels are for the raw stock and the open reels are

for the negative. The circular pulley in the center is the heavy flywheel on

the printing drive to insure smooth motion.

After

our discussion of the Mark III Printer on July 11 [1957], I promised to write

up a description of the principle which distinguished it from the

earlier Mark II model. The incentive for developing the Mark III was

primarily to get increased printer speed and hence print output.

The

only ways to accomplish this were:

1) Increase light source brightness,

2) Increase lens speed,

3) increase printer slit width.

The light source

problem was being considered but tungsten lamps were the only practical

solution at the time and were already being used at maximum brightness

levels. The printer lens speed was already at the borderline of adequate

image sharpness and no substantial increase seemed feasible. This left

only the printer slit width. Printer speed being directly proportional

to slit width

indicated it

would be desirable to find some way to increase this by a factor of two

or more.

In

the Mark III the slit width is limited by two things: 1) for anything

but zero "droop" correction, the image of the negative does

not coincide with the print film at all points but rather it intersects

the print film at an angle which increases with increasing

"droop" and which is equal to twice the bridge angle (i.e.

angle of incidence of light on print film). This means that the image is

in focus on the print film at only a single line and thus a given point

on the negative is in focus only during the instant it crosses this

line. On either side of this line it goes out of focus to a degree

depending on the distance and on the angle. For a droop corresponding to

the requirements of a theater like the

Rivoli, the bridge angle is about

45°

and the image makes an angle of 90°

with the print film. In this case a slit width of about 0.010 inch is

all that can be tolerated, before image blur becomes objectionable.

The

other factor that limits the slit width is the amount of transverse

motion of any given image point (especially near the edge of the

picture) due to the change in magnification resulting from the

oscillating lens. This change in magnification is necessary to produce

the corrections for keystoning in the theatre (K-correction) and for

vertical line curvature from the camera lens distortion (A-1

correction). For the case of K-correction alone, the transverse motion

at the edge of the film occurs at a rate of almost 1/5 that of the

longitudinal motion picture and hence a slit width of 0.010 inch allows

a transverse blur of about 0.002 inch multiplied by an additional factor

because the effective slit width is increased by the oblique incidence

of light onto the film print. The addition of A-1 correction aggravates

this transverse blur still further, particularly in the upper corners of

the frame.

|

Further

in 70mm reading:

Todd-AO Equipment

Catalog

Part

1:

Todd-AO

Distortion Correcting Printing Process

Part 3:

"Oklahoma!"

Printing

Operation

in the Todd-AO Mark III Printer

The Rivoli Theatre

Internet link:

|

Benny Grinsewitz focusing the optical system. Benny Grinsewitz focusing the optical system.

In

the Mark III printer the optical system has been modified so as to

eliminate both the blur due to the angle between image and print film

and the transverse blur due to K-correction. The first of these was

accomplished by replacing the Amci (90°

roof type) prism at one end of the bridge by a regular 90°

prism identical to the one already being used at the other end of the

bridge. In this way the image and the print film were caused to coincide

at any bridge angle, neglecting for the moment the curvature of the

negative over the guide rollers and the curvature of field of the

printer objective lens system. Both of the latter are far less important

in causing blurring of the image than certain other effects.

This

change in the optical system by itself, without the oscillating lens

action, would cause a transverse blurring which is comparable to that

mentioned previously since, in this case, the instantaneously-formed

image on the print film is itself keystoned. Thus the image of any

off-center point on the negative does not travel parallel to the print

film during printing but at an angle which increases towards the edge of

the film. Here then lies the crux of the Mark III principle. By

introducing just the right amount of opposite transverse motion for each

point of the image using the oscillating lens, it is possible to

compensate this "intrinsic" keystoning and eliminate this

source of blurring. Now at the same time this will produce the desired

overall keystoning of the image of the frame on the print film because

as each elemental horizontal strip of the negative passes over the

printer slit, it will be magnified by a different amount due to the

oscillating lens just as in the Mark II printer.

In

summary, therefore, the Mark III makes it possible to print a keystoned,

drooped image using a substantially wider slit. The A-1 corrections

however, again cause some transverse blurring which now is most

noticeable in all corners of the frame. This together with the curvature

of the negative and the curvature of field of printer lens (which

unfortunately add to one another, rather than cancel) now limit the slit

width.

|

|

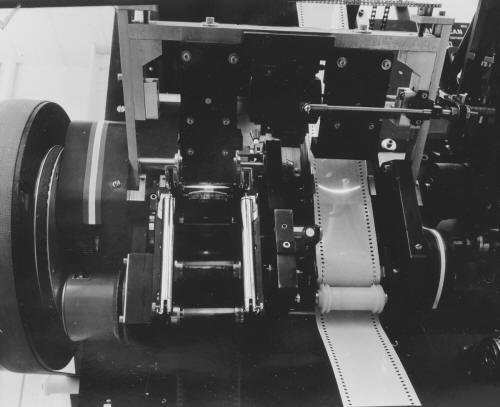

Printing section showing on left the negative slit illuminated in

straight line & on the right the print stock on the curved shoe & slit

illuminated with a curved line (The B, or “Droop” correction). Printing section showing on left the negative slit illuminated in

straight line & on the right the print stock on the curved shoe & slit

illuminated with a curved line (The B, or “Droop” correction).

When

the Mark III was tested in actual printing operation it was found that a

slit of 0.030 inch or three times the Mark II could be tolerated at a

bridge angle of 45°

and about 0.040 inches at a bridge angle of 38°.

Thus factors of 3 to 4 in speed could be realized, other things being

equal. Actually various other changes particularly in the light source

optical system were made which make a direct comparison invalid.

The

problem of obtaining any given overall frame keystone correction

(K-correction) along with any given droop while at the same time

matching the "intrinsic" printer keystone requires the control

of several factors in the printing system. The focal length of the

printer lens and the bridge angle determine the intrinsic keystone. The

curvature of field of the printer lens and the bridge angle determine

the droop. The overall frame of K-correction is a function of the shape

of the cam which drives the oscillating lens and must be such as to

compensate the intrinsic keystone. Thus for a given K-correction and

droop it will, in general, be necessary to specify the printer lens

focal length, the bridge angle, the cam design and the curvature of the

print film guide or "shoe" which curves the print film to fit

the image curvature. Fortunately a family of useful sets of

K-corrections and droops corresponding to practical theatre conditions

can be realized using only one printer lens focal length, by changing

bridge angles, cams and print film "shoes". A change over from

one sets of these conditions to another is not very simple, however,

because several critical adjustments such

as phasing of the cams with the frame line and balancing the

focus of the oscillating lens are required to obtain best performance.

One

other change in the printer lens of the Mark III might be noted. The

matching of intrinsic keystone with K-correction requires, in general, a

longer focal length printer lens than used in the Mark II and this

introduces a new distortion into the printed picture, namely, a

horizontal expansion of objects near the edges of the picture (in very

much the same way as projection on a curved screen compensates for the

barrel distortion in the camera lens). This is a very undesirable effect

for scenes taken with long focal length camera lenses since now this

horizontal expansion would occur twice, once in the printer and again on

the screen. To eliminate this effect in the printer, an aspherical lens

similar to the type used in the 128°

camera lens was used as one element of the printer lens system (the

element nearest to the negative film). This effectively reduces the

horizontal magnification for objects near the edges of the picture

without changing the vertical magnification and cancels this source of

distortion.

|

|

| |

|

Go:

back

- top

-

back issues

Updated

21-01-24 |

|

|

Benny Grinsewitz focusing the optical system.

Benny Grinsewitz focusing the optical system. Printing section showing on left the negative slit illuminated in

straight line & on the right the print stock on the curved shoe & slit

illuminated with a curved line (The B, or “Droop” correction).

Printing section showing on left the negative slit illuminated in

straight line & on the right the print stock on the curved shoe & slit

illuminated with a curved line (The B, or “Droop” correction).