The Technirama Story

|

This article first appeared in |

| Written by: Grant Lobban | Issue 61 - June 2000 |

Technirama

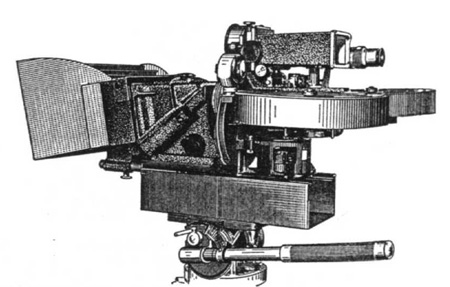

Delrama lens. The bigger one is from the Technicolor camera department and

was for their Technirama camera number 8G. The smaller is one made for 8mm.

Marty Hart, American Widescreen Museum Technirama

Delrama lens. The bigger one is from the Technicolor camera department and

was for their Technirama camera number 8G. The smaller is one made for 8mm.

Marty Hart, American Widescreen MuseumMost accounts of Technicolor's achievements concentrate on their famous 3-strip colour camera and dye-transfer printing process, which held a virtual monopoly of colour filming during the 1930s and 1940s. Full descriptions of the Technicolor 3-strip colour process, (not to be confused with Cinerama´s 3-strip widescreen system), have been published many times before, but basically it was a photo/mechanical procedure, akin to colour lithography, but printing the images onto transparent film instead of paper. In the camera, three black and white negatives were exposed behind a beam-splitter, recording the separate red, green and blue components of the scene. These three separation negatives were then used to make "matrices'', which carried positive relief images made up of hardened gelantine. These were used, like printing a plate, to transfer in turn, cyan, magenta and yellow dyes, in register, onto blank film, building up the complete colour picture. By today's standards, and even compared with black and white films of the time, Technicolor dye-transfer colour prints had poor definition and sometimes showed signs of being a little out of register. However, these failings were more than compensated for by their higher contrast and vivid highly saturated colours, which made Glorious Technicolor look good, particularly on the modest sized screens used in cinemas during the 1930s and 1940s. The first threat to the process came at the start of the 1950s, with the arrival of Kodak's Eastman Color single-strip multilayer colour film. This could be used in a conventional camera and then processed and printed by any laboratory equipped to do so. The new stock also made it possible to introduce the various widescreen systems, for showing on much larger screens. Technicolor soon adapted its process to allow their matrices to be made directly from the new colour negatives. Although the colour was often superior, the resulting dye-transfer prints were less sharp than those made on Eastman Color print film. They compared unfavorably, when subjected to the greater magnification needed, when the image was either "cropped" and enlarged onto a wider screen, or stretched out sideways, as in CinemaScope. Technicolor started an urgent development programme to improve the sharpness of their prints. They asked Kodak, who had traditionally supplied all of their film materials, to provide better quality matrix stock. At first Kodak was reluctant to do so, suggesting that Technicolor, like other laboratories, such as Consolidated, De Luxe and Metrocolor adopt the Eastman Color process. However, although Technicolor began to phase out its 3-strip camera, in favor of colour negative, the company was determined to improve their unique printing system and continue to offer the industry the option of using dye-transfer prints. For a while, Technicolor obtained higher quality stocks from other suppliers, like DuPont in the U.S.A. and Ferrania in Europe, but then, Kodak, realizing that Technicolor meant business and not wishing to lose one of its biggest customers, came up with higher definition matrix film. By 1954, dye-transfer prints were not only able to record all the detail from the original colour negative, but also benefit from reduction printing. Reduction printing produces finer-grained and higher-definition prints by exploiting the fact that print film has higher resolution than camera film, so can record all the extra detail obtained by using a larger negative in the camera. (Up to about 3 times larger was considered to be the limit.) The principle had already been tried out briefly in the early 1930s, with processes like the M.G.M.'s Realife and U.A.'s Magnifilm widescreen system. These used larger 70mm and 65mm films in the camera, which were then reduced down to 35mm for projection onto larger-than-normal screens. Nothing came of it then, but the idea was revived again in 1954, when Paramount and Technicolor jointly developed the VistaVision process. In this case, the larger negative was obtained by running standard 35mm film horizontally through the camera, exposing an 8-perforations frame, with an image over twice the normal size. This was then optically reduced to produce a normal 4-perforation vertical pull-down dye-transfer print, but with a much higher quality image, which was more suitable for cropping and showing on a larger and wider screen. The printed image had an aspect ratio of 1.43:1, but was usually masked down to produce a 1.85:1 picture on the screen. |

Further in 70mm reading: |

Birth of a process |

|

Although Technicolor was producing beautiful VistaVision prints for Paramount, the process was only being used occasionally by other studios. Most producers thought that their audiences would be more impressed by CinemaScope´s wider screen, rather than better picture quality. Although Technicolor was producing beautiful VistaVision prints for Paramount, the process was only being used occasionally by other studios. Most producers thought that their audiences would be more impressed by CinemaScope´s wider screen, rather than better picture quality.Technicolor decided to introduce its own proprietary widescreen process combining the benefits of both. Their aim was to bring VistaVision quality to CinemaScope-type anamorphic squeezed prints and at the same time, help to ensure the future of its dye-transfer matrix printing system. Development work began at their London plant under the supervision of engineer George Gunn. The new system was to be based on using a large-area camera negative, which could be used to produce every kind of 35mm and 16mm print then in current use. This would need extensive use of optical printing. This had always been part of the normal Technicolor process, needed to produce the printing matrices, so it was going be, according to Technicolor, "right up our street". Known during its development work, as the "Technicolor Universal Frame Process'', the negative was to be the same as Vista Vision's 35mm horizontal double-frame format, but with the aspect ratio of the image increased to that of CinemaScope´s 2.35:1, by using anamorphic lens on the camera. As the VistaVision frame was already a little wider, a lateral compression factor of 1.5X. was to be employed, which was only half that of CinemaScope's 2X. This large compressed negative image could then be squeezed further (XI.33) during the reduction to make prints compatible with CinemaScope, or unsqueezed for "flat" prints, mostly in the 1.85:1 ratio. Technicolor had already converted several of its now redundant 3-strip cameras to the VistaVision format, replacing the triple film beam-splitting system, with a single horizontal 8-perf. movement. With new purpose-built VistaVision cameras now coming off the Mitchell Camera Company's production line, these became available for Technicolor's own system. The first major problem was to obtain a high quality anamorphic camera lens to match the overall quality of the system. First tests using a lens designed and made up for Technicolor in France were disappointing. It had many of the optical problems associated with early cylindrical refracting anamorphic lenses, including variation of the compression factor across the frame and at different focusing distances. After unsuccessful attempts to find other lenses via the Hollywood plant, Frank Durban, General Manager of J. Frank Brockless Ltd. suggested trying the Dutch Delrama system, of which they were the British distributors. (The company also handled the Philips range of projection equipment in the U.K., which later was to include the DP70.) The Delrama anamorphic reflecting system used curved mirrors arranged in the form of a periscope, instead of the more usual lenses or prisms, and was free of many of their defects. Tests using a modified projection unit were encouraging, so Frank Durban and representatives from Technicolor traveled to the Netherlands to meet its creator Dr. A Bouwers of NV Optishce Industrie De Oude Delft. He seized upon the problem and came up with a design more suitable for camera use. This employed specially computed curved surface reflecting prisms, rather than cylindrical lenses or refracting prisms. It was an auxiliary attachment big enough to cover the larger diameter of the lenses needed to cover the double-frame negative and allowed for a maximum angle of view of about 60-degrees, equal to that of CinemaScope and the other systems then in use for general film making. The prototype was tested by being sent to the winter sports resort at Sestriere, with instructions to shoot a wide variety of scenes in all kinds of lighting conditions, particularly with the sun glaring off the snow, to make sure that the prime lens and Delrama combination produced no internal reflections. The results were superb, even at wide apertures, so Technicolor obtained exclusive rights throughout the world to use the Delrama, so it would only be used as part of its own widescreen system. The name Technirama was finally chosen for the system, said to be coined from the words Technicolor and Delrama. (Delrama anamorphic attachments, using the same principle, were made available for 8mm and 16mm users and marketed under the name Vistascope in the U.S.A.). |

|

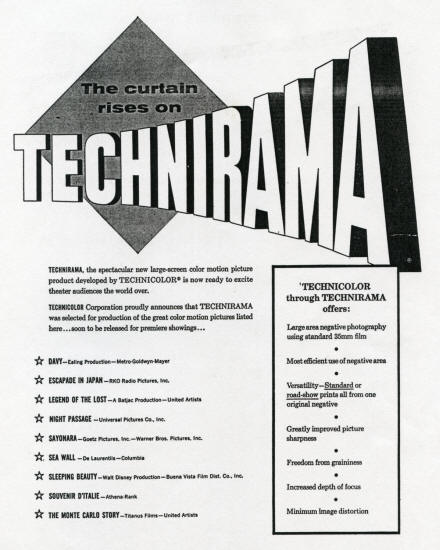

The Curtain Rises on Technirama |

|

The Sestriere footage was incorporated into a promotional short Technirama demonstration film called

"The Curtain Rises On Technirama", which was used to help introduce the process to the industry in 1956. The principal release format was to be 35mm Anamorphic dye-transfer prints, with the option of unsqueezed 1.85:1 prints if required. Apparently Technicolor made a lot of these at the time to German cinemas. At first, it was suggested that horizontal 8-perf. contact prints (on Eastman Color print film) be used for

special first-run road - show engagements. These would be available with a single optical, or multiple magnetic sound tracks. The idea of horizontal prints had already been tried out with VistaVision. Technicolor had actually made a few prints, but they only had limited use, due mainly to the fact that they required additional special projectors, which couldn´t run normal prints. It was thought that the arrival of Technirama horizontal prints would revive the format. The British projector manufacturer Gaumont-British Kalee produced a fine horizontal machine for showing VistaVision or Technirama films. For the latter, Taylor-Hobson made a prismatic 1.5X anamorphic attachment, which restored the squeezed image by compressing it vertically, rather that expanding it horizontally, which was said to give better results. Unfortunately, events would show that they had "backed the wrong horse" and it would have been better to make a 70mm projector. The Sestriere footage was incorporated into a promotional short Technirama demonstration film called

"The Curtain Rises On Technirama", which was used to help introduce the process to the industry in 1956. The principal release format was to be 35mm Anamorphic dye-transfer prints, with the option of unsqueezed 1.85:1 prints if required. Apparently Technicolor made a lot of these at the time to German cinemas. At first, it was suggested that horizontal 8-perf. contact prints (on Eastman Color print film) be used for

special first-run road - show engagements. These would be available with a single optical, or multiple magnetic sound tracks. The idea of horizontal prints had already been tried out with VistaVision. Technicolor had actually made a few prints, but they only had limited use, due mainly to the fact that they required additional special projectors, which couldn´t run normal prints. It was thought that the arrival of Technirama horizontal prints would revive the format. The British projector manufacturer Gaumont-British Kalee produced a fine horizontal machine for showing VistaVision or Technirama films. For the latter, Taylor-Hobson made a prismatic 1.5X anamorphic attachment, which restored the squeezed image by compressing it vertically, rather that expanding it horizontally, which was said to give better results. Unfortunately, events would show that they had "backed the wrong horse" and it would have been better to make a 70mm projector. |

|

| What About 70mm? | |

Even when first announced, the possibility of adding 70mm to the range of prints available from the versatile Technirama negative was discussed. However, at the time, although

Todd-AO and 70mm projection was making news in America, it had yet to make any impact elsewhere. For example, it couldn't be seen in Britain for another two years. For the moment, horizontal 35mm prints were being promoted in the U.K. as Technirama´s prestige format. The first Technirama feature,

"The Monte Carlo Story", starring Marlene Dietrich, was premiered this way at the Reposi Cinema in Turin in December 1956, using an Italian Micronlamda VistaVision horizontal format projector with a 1.5X anamorphic lens. Even when first announced, the possibility of adding 70mm to the range of prints available from the versatile Technirama negative was discussed. However, at the time, although

Todd-AO and 70mm projection was making news in America, it had yet to make any impact elsewhere. For example, it couldn't be seen in Britain for another two years. For the moment, horizontal 35mm prints were being promoted in the U.K. as Technirama´s prestige format. The first Technirama feature,

"The Monte Carlo Story", starring Marlene Dietrich, was premiered this way at the Reposi Cinema in Turin in December 1956, using an Italian Micronlamda VistaVision horizontal format projector with a 1.5X anamorphic lens.The initial option of making horizontal prints led to different practices regarding the camera apertures and printed areas in use on either side of the Atlantic. Cameras supplied by Technicolor's European plants used an aperture of 1.480in. X 0.915in., leaving a clear area above the image for the soundtrack. Hollywood's view was that, with the failure of VistaVision horizontal prints to catch on, Technirama horizontal prints wouldn't be needed, so their cameras had an aperture of 1.496in. X 0.992in. This meant that the first American prints were reduced from a slightly larger negative area. Also, the Hollywood plant was already gearing up to handle the 65mm/70mm systems. They would soon be making 35mm dye-transfer reduction prints from Todd-AO and M.G.M. Camera-65 65mm negatives, alongside those made from their own Technirama large-area system. The first Hollywood Technirama feature was Universal-international's "Night Passage" in 1957. (Often quoted as the first ever Technirama film.) The first British production was Ealing Studio's "Davy" (1957). The process proved to be reasonably successful in its original form, but later in 1959, the option of 70mm prints was finally added to its list of available formats and "Super Technirama 70" was born. |

|

Super Technirama 70 |

|

By 1958, 70mm was becoming well established, helped by the availability of multi-purpose 70mm/35mm dual gauge projectors. 65mm/70mm processing and printing facilities were now being installed in Technicolor's London and Rome laboratories. The dye-transfer system was never adopted to make 70mm prints, with all Technicolor's 70mm prints being made directly on to Eastman Color positive print film. The first Technirama 70mm print was made for Walt Disney. Always closely associated with Technicolor, they had made their cartoon feature

"Sleeping Beauty" (1959) in Technirama and wanted to give it the added status of a 70mm release. It was photographed in the Technirama format using a cartoon camera which photographed each of the cells three times through red, green and blue filters in sequence along a single black and white negative. The squeeze was incorporated by a lens supplied by Panavision and this was to form the basis of the printer lens needed to make the 70mm print. Similar lenses were also obtained from Cooke Taylor-Hobson. By 1958, 70mm was becoming well established, helped by the availability of multi-purpose 70mm/35mm dual gauge projectors. 65mm/70mm processing and printing facilities were now being installed in Technicolor's London and Rome laboratories. The dye-transfer system was never adopted to make 70mm prints, with all Technicolor's 70mm prints being made directly on to Eastman Color positive print film. The first Technirama 70mm print was made for Walt Disney. Always closely associated with Technicolor, they had made their cartoon feature

"Sleeping Beauty" (1959) in Technirama and wanted to give it the added status of a 70mm release. It was photographed in the Technirama format using a cartoon camera which photographed each of the cells three times through red, green and blue filters in sequence along a single black and white negative. The squeeze was incorporated by a lens supplied by Panavision and this was to form the basis of the printer lens needed to make the 70mm print. Similar lenses were also obtained from Cooke Taylor-Hobson. The first live action customer to get the 70mm blockbuster treatment was "Solomon and Sheba" also in 1959. In both cases, the decision to make 70mm prints was made shortly before release, so both films only carried the normal Technirama credit in their titles, although much was made of the "new" Super Technirama 70 process on the posters and other promotional material. The process was given a further boost with the success of "Spartacus" (1960), with the full credit now appearing in Saul Bass's wonderful opening credits. Incidently, on this particular film, Panavision also received a credit. This only refers to its printer lens, the camera still used the Delrama anamorphic system. (Apparently, some later Delramas were also assembled for Technicolor in the U.S. by Bausch & Lomb.) Super Technirama 70 prints were fully compatible with Todd-AO and the other systems using a spherical 65mm negative. Although technically a blow-up, this was only needed in one direction. The height of the Technirama negative already matched that of a 5-perf. 70mm print, so it was only necessary to un-squeeze the image to fill the frame. Coming from a negative less than two thirds the size, the image admittedly appeared a little grainier than contact prints from 65mm originals. However, the results on the screen were still often stunning, fine examples being "El Cid" and "Zulu". Technicolor took great care when making their 70mm prints. The negatives were specially processed (zircotan bleach) to give them an image with the grain and contrast characteristics more suitable for optical printing. As the number of prints were relatively small, the original negative was always used. (After making black and white separation protection masters.) A liquid gate printer helped to hide any blemishes. In this technique, pioneered by Technicolor, the negative was immersed in a chemical solution having the same refractive index as the film's base. This had the effect of "filling in" any scratches on the base side of the film so they wouldn't show up on the print. Sometime, the only clue that a Technirama 70mm print was being shown, was the rare sight of a negative emulsion scratch running horizontally across the screen and sometimes, if misframed in the projector, impressions of the eight negative perforations showing along the bottom frame line. More recent 70mm reprints of Technirama films can not always recreate the original quality. For example, the recent 70mm restoration of "Spartacus" wasn't made from the original negative, which was found to have faded, but was contact printed from a new 65mm duplicate color negative generated from the Technirama format B&W protection color separations. |

|

Continued Developments |

|

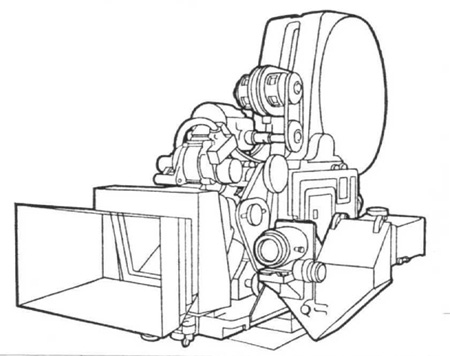

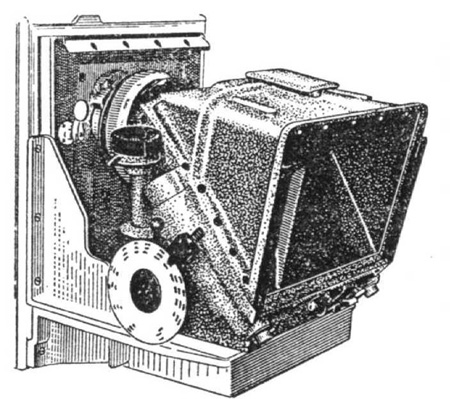

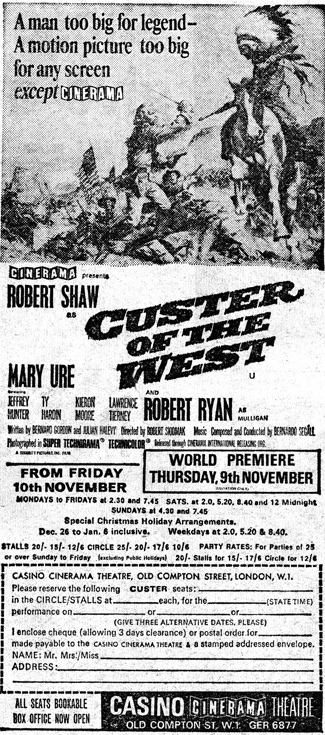

Trade

advert for Technicolor's Technirama process. Trade

advert for Technicolor's Technirama process. Click to see enlargement Technicolor engineers continued to develop the process. Although they continued to use the old converted 3-strip cameras, these had a state-of-the-art motorized follow-focus system to adjust the prime lens and Delrama simultaneously. At first, the original huge 3-strip blimp, which occupied some sixteen cubic feet of studio space, was used for sound shooting and, with the film running at twice the normal speed, the 1000 foot magazines meant constant reloading. Later a small fiberglass blimp, only a third of the weight, was engineered, together with special 2000 foot coaxial magazines. Technicolor now boasted that the Technirama camera could be moved around by only two men! A Mitchell lightweight VistaVision camera was also adapted for Technirama and an underwater housing constructed. One important advantage over the other large-area systems was that Technirama still used standard 35mm film in the camera. This made it particularly popular outside America, where 65mm processing facilities were limited. The negative could be processed by any laboratory and Technicolor could also provide a mobile printer installed in a caravan (trailer) for making 'Scope reductions of the rushes without delay. Two such vehicles were equipped and sent to locations all over the world, one traveled as far as Japan. The most dedicated European user was producer Samuel Bronston, choosing to make most of his epics in Technirama, including "King of Kings", "El Cid", "55 Days at Peking" and "Circus World" (G.B. title "The Magnificent Showman"). The latter was shown in 70mm Single-Lens Cinerama, who supplied Technicolor with a special printer lens which left the image at the sides at the frame slightly squeezed. This corrected itself when shown on Cinerama´s deeply-curved screen. At one time, a printer set-up was even constructed to convert Technirama to 3-strip triple panel Cinerama. A couple of Technirama films, Michael Powell's "Honeymoon" (1959) and "Black Tights" (1960) (Alternative title: "One, Two, Three, Four"), were converted to ARC-120. (Not done by Technicolor). This curious process unsqueezed the image, divided it down the centre and printed the two halves side-by-side vertically within a normal 35mm frame. The resulting print was shown through a special twin-lens projector attachment, which reassembled the image onto a deeply-curved screen. (More about ARC-120, also known as Thrillarama, will appear in a later issue of The 70mm Newsletter). Technirama films continued to be made without having 70mm prints made. Actually the credit "Filmed in Super Technirama 70" could be described as misleading. The 35mm release prints were no different from "ordinary" Technirama films, with no 70mm stock involved in the process. Anyway, nobody ever complained and it looked more impressive on the titles. The last Super Technirama 70 film was another Cinerama presentation, "Custer of the West" in 1967. With constantly improving film stocks, producers no longer felt that the added cost of using double the amount of negative stock was justified. If needed, satisfactory 70mm prints could now be made by blowing up a 35mm anamorphic negative. And at the other end of the picture quality scale, Technicolor was now finding more customers for its 2-perforation pull-down "half-frame" Techniscope process. Disney revived Technirama in 1985 for its animated feature, "The Black Cauldron", before the process was finally put back on the shelf. Fortunately many notable features were made in Technirama (see list) and with many now to be seen on TV and video, the trademark on the credits will help keep the memory of this fine widescreen process alive. |

|

Cites Advantages of Technirama Process |

|

"A splendid future" is foreseen for Technirama, new Technicolor widescreen process, by Marcello Girosi, executive producer of Titanus Films´

"The Monte Carlo Story", which United Artists will release here in 1957. Marlene Dietrich and Vittorio de Sica star. Mr. Girosi describes the new process, which employs film traveling horizontally through the camera as "two-fold in the benefits". The first of these, he said is "the wonderful detail, the superb focus, which catches natural beauties, and details as much as a thousand feet away". The second, he added, was "the possibility of printing in any format required, such as CinemaScope, VistaVision, regular 35mm etc". He also told a trade press conference at Hampshire House in New York last week that the process is being studied currently by several American producers with a view to its use in the near future. "A splendid future" is foreseen for Technirama, new Technicolor widescreen process, by Marcello Girosi, executive producer of Titanus Films´

"The Monte Carlo Story", which United Artists will release here in 1957. Marlene Dietrich and Vittorio de Sica star. Mr. Girosi describes the new process, which employs film traveling horizontally through the camera as "two-fold in the benefits". The first of these, he said is "the wonderful detail, the superb focus, which catches natural beauties, and details as much as a thousand feet away". The second, he added, was "the possibility of printing in any format required, such as CinemaScope, VistaVision, regular 35mm etc". He also told a trade press conference at Hampshire House in New York last week that the process is being studied currently by several American producers with a view to its use in the near future. |

|

| Go: back

- top - back issues Updated 21-01-24 |